The ceiling in a wooden house has its own specifics. Already at the design stage, it is necessary to pay worthy attention to this issue, having determined the design and method of final finishing. An important condition is the maximum exclusion of heat leakage through the cracks, do not forget about the aesthetic aspect, which is solved by design projects and trifles. The ceiling can even be made with your own hands, but taking into account the recommendations of experts and safety requirements.

Design features

A wooden house is characterized by the absence of strong reinforced concrete floors that create a load-bearing surface. The ceiling is formed during construction. It consists of a timber floor with joists, a deck and a topcoat. Mandatory elements: hydro, steam and thermal insulation.

In fact, the structure is made up of 2 parts - a rough and a final ceiling.

The draft ceiling plays the role of a ceiling slab and provides protection against any external influences. Finish ceiling forms the appearance of the structure.

The ceiling of a wooden house should be light, but strong and have thermal insulation properties. Materials for it are selected taking into account the following requirements:

The main advantages of a wooden house are naturalness, special microclimate, good natural air circulation, heat retention. The ceiling should not impair these characteristics and fit harmoniously into the structure of the structure.

How to make a rough ceiling

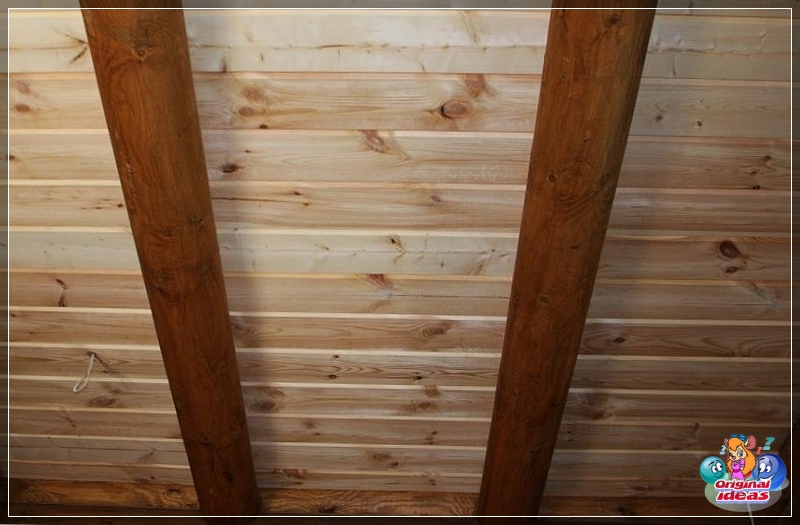

For the manufacture of a black ceiling, first of all, it is necessary to lay a floor of wooden beams. They cut into the upper crown of the frame and are securely fixed with anchors. The most commonly used beam is 12-20 cm. Recently, preference has been given to a wooden bar measuring 4x15 cm with its installation on the smaller side (edge). To fix the flooring on the beams, cranial bars are installed on the side.

The next step is making the flooring, t. e. joist sheathing. It is made of an unedged board with a thickness of at least 20 mm, a width of at least 15 cm. The question of how to sheathe a rough ceiling can be solved by using sheet products plywood sheets (at least 12 mm thick), MDF panels, OSB boards. Sheet and tile materials simultaneously provide leveling of the ceiling surface, which facilitates further finishing.

Before installation, all wooden parts must be impregnated with an antiseptic composition. It is recommended to carry out impregnation 2 times. Installation of machined parts can only be started after complete drying of the material.

Protective covers

By design, the ceiling is a "puff cake". It must perform protective functions, and therefore contain the following layers:

Sound insulation (noise insulation) is usually not applied separately. Almost all heaters are capable of performing this function. In addition, the wood itself helps to increase noise immunity.

How to make a fine ceiling

After the manufacture of the supporting part of the ceiling (draft ceiling) and the laying of protective layers, the question arises of how to cover the ceiling surface from the inside to give it an attractive appearance. Finishing the ceiling in a wooden house (making a final ceiling) implies leveling the surface and finishing. It can be done in different ways depending on the type of outer coating. Almost any finishing option can be provided on a wooden ceiling, depending on the style of the interior and the wishes of the owner.

Surface leveling

If it is supposed to use traditional methods for finishing a wooden ceiling - whitewashing or painting, then its surface must be carefully leveled. For this, sheet materials are installed on the flooring of the rough ceiling. The most commonly used plywood and drywall. You can use MDF panels, chipboard and other similar products.

Drywall is especially popular due to its affordable price and ease of cutting and installation.

When working with it, one important drawback must be taken into account - the high risk of damage to the edges and corners of the sheets. That is, care is required during transportation, storage and installation. Plasterboard sheets are attached to the flooring with self-tapping screws, while the caps are recessed by 1-2 mm. The gaps between the sheets and the attachment points are putty, and then the entire surface of the ceiling is covered with a layer of primer.

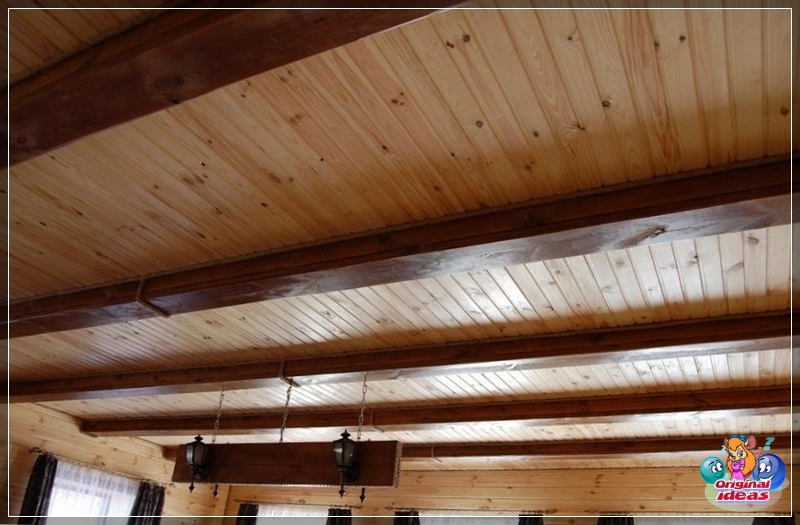

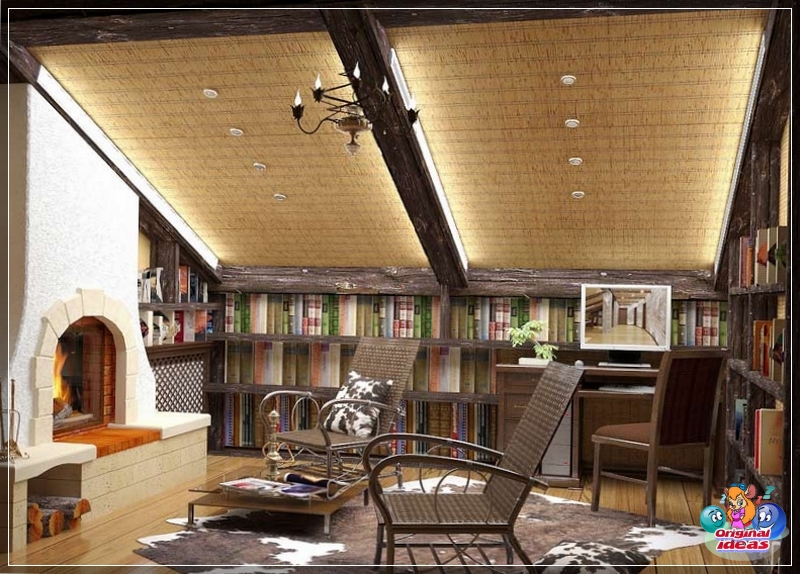

Wood finish

Wood ceiling decoration is most in harmony with a wooden house. The naturalness of the structure is emphasized not only outside, but also inside. The following technology is most often used: a frame in the form of a lattice from a wooden bar is mounted on a rough ceiling. Wooden facing elements are fixed on it from below. This is how a kind of false ceiling is formed. Its main advantages are masking all the irregularities of the floor and the possibility of laying various highways and electrical wiring.

The following wood products are used as facing materials:

1. Lining. It represents narrow, rather long strips (slats) made of natural wood. To connect the elements to each other, a locking profile is made on the edges. The following types of lining are distinguished:

2. Veneered panels. In fact, this is an Economy-class lining, on the surface of which veneer from a valuable species of wood is glued. The result is the appearance of a rich ceiling cladding;

3. Array. It is made from cuts of expensive wood in the form of large panels. With a tight joining of the array, the ceiling seems to be monolithic. This material is highly durable and durable.

In addition to the main finishing options, sometimes other wood products are used for ceiling cladding - wooden siding, timber, embossed panels. Special attention should be paid to the artistic wood panels and elements of the ceiling decor. In these cases, wood carving technology and painting are used. Such panels are expensive, but allow you to create a real "fairy tale" on the ceiling.

Plastic finish

Another option for a suspended ceiling is made using plastic panels. Usually PVC panels are applied. For this, a frame is mounted from an aluminum or plastic profile. The length of the panels reaches 6 m and the width is 10-30 cm. All elements have a lock connection, which allows them to be tightly joined together. Panels are fixed in plastic guide profiles, which in turn are attached to the frame.

The panels have a different color and pattern, which allows them to be matched to the desired design style. The main advantages of such a finish are water resistance, ease of do-it-yourself installation, maintainability, the possibility of wet cleaning, an attractive appearance. Disadvantages - low mechanical strength during punching and cutting action, flammability.

Stretch ceiling

A modern way of finishing - stretch ceiling. The essence of the method lies in the formation of an additional ceiling surface under a rough ceiling from a sheet stretched horizontally. The tensioning system design consists of a baguette (frame), ceiling panel, fasteners and decorative overlays.

Taking into account the material of the canvas, such structures are divided into 2 main types - film (plastic) and woven (seamless) ceilings. In the first case, a fabric made of PVC film is used, and in the second, a polyester knitted fabric.

Installation of tensioning systems is carried out as follows. First, at a distance of 3-5 cm from the ceiling, a baguette is mounted from special metal or plastic profiles with fasteners. Then a canvas is pulled into it, which is evenly stretched. PVC film is mounted with preheating to 60-65 degrees using a heat gun or a powerful construction hair dryer. When cooled, it shrinks, which provides uniform tension. The fabric is stretched mechanically, manually, without heating.

Stretch ceilings are particularly decorative. The canvas can have a different color, as well as patterns or patterns. Photo printing is widely used. According to the type of surface formed, such options differ - matte, glossy and satin ceiling. The fabric is most often matte or satin type. You can apply any drawing with paints on it yourself.

The advantages of this system are the absence of the need to level the ceiling surface, masking the wiring and all visible defects, and an attractive appearance. Disadvantages - complicated installation, the need for special equipment when using PVC film, high cost.

Conclusion

In a wooden house, the ceiling is made already at the construction stage, and not after its completion. When arranging it, it must be borne in mind that a wooden floor is inferior in strength to reinforced concrete slabs, which means that it requires taking into account real loads. In general, with the right choice of finishing method and competent work, installation can be done by hand. At the same time, the ceiling will harmoniously fit into the overall interior of the room and have an attractive appearance.