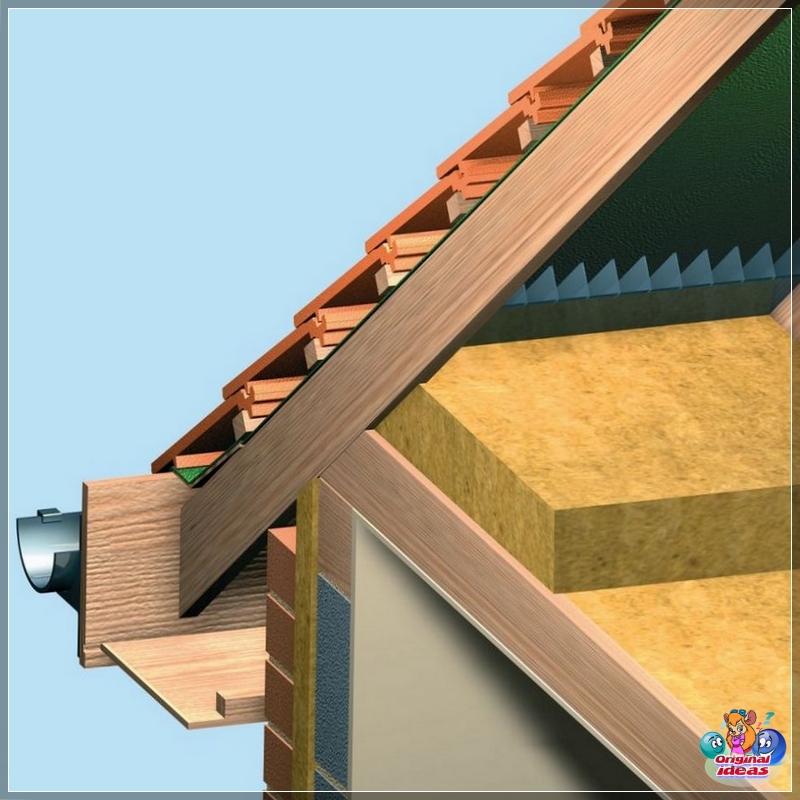

In modern construction, insulation materials are actively used, which preserve the microclimate in the house as comfortable as possible for its residents. It is known that the main losses of heat energy fall on the ceilings and roofs of buildings, therefore builders pay a lot of attention to their thermal insulation.

Not so long ago, the list of heaters was limited to a few points, and the materials listed in it did not differ in manufacturability. In older houses, roofs are usually not equipped with thermal insulation, therefore, heating systems in buildings operate with low efficiency. Roof insulation works are often time-consuming, the better the result is achieved after replacing the roofing material. Ceiling insulation in a house with a cold roof is an alternative solution to the problem of keeping warm in rooms.

Both traditional and modern materials are suitable for the installation of thermal insulation of ceiling ceilings, allowing work both indoors and above it. The main thing is that they are fire-resistant and harmless to health. When choosing a heater, you should consider where it will be mounted, what additional materials will have to be purchased.

Warming with traditional materials

In some cases, it is more expedient to use traditional materials to insulate the ceiling in a house with a cold roof. They are easy to cover a horizontal plane. In addition, the well-known insulation materials do not raise doubts about environmental safety. This type of insulation is suitable for all floors. It can be used to cover any ceiling:

Traditional methods do not allow the room to be insulated from the inside, but this cannot be called a drawback.

An insulator layer above the ceiling protects it from external influences, in addition, thermal insulation under the ceiling affects the height of the room.

It can be concluded that internal insulation should be carried out in the absence of the possibility of installing thermal insulation from the outside.

Traditional types of thermal insulation include clay, expanded clay, straw, sawdust and glass wool. They can be used to insulate the ceiling in a wooden house. Its overlap is a beam structure, to which ceiling strips are hemmed. Before installing the heat insulator, it is necessary to cover the ceiling with a waterproofing membrane. It will protect the wooden elements of the ceiling from contact with wet clay, and glass wool and other heaters from saturation with water vapor, after which the thermal protection will lose its performance.

Clay insulation

Straw and sawdust retain heat well, but are so flammable that they are best used as one of the components of the solution. For example, sawdust and clay can be used to make a cheap ceiling with low thermal conductivity. The disadvantage of this method is the long drying time of the solution. You can use straw as a filler for clay mortar. An additional component of the insulation is slaked lime. It will strengthen the thermal insulation and give it antiseptic properties.

The scheme for the preparation of insulation and its bookmarks is as follows.

Despite the presence of lime and sawdust, the clay heat insulator can crack when it dries, so it is better to apply it in layers, leveling and tamping each layer, rubbing the cracks that appear as the solution dries. Sometimes copper sulfate (50 g / 10 l) is added to the water prepared for the solution.

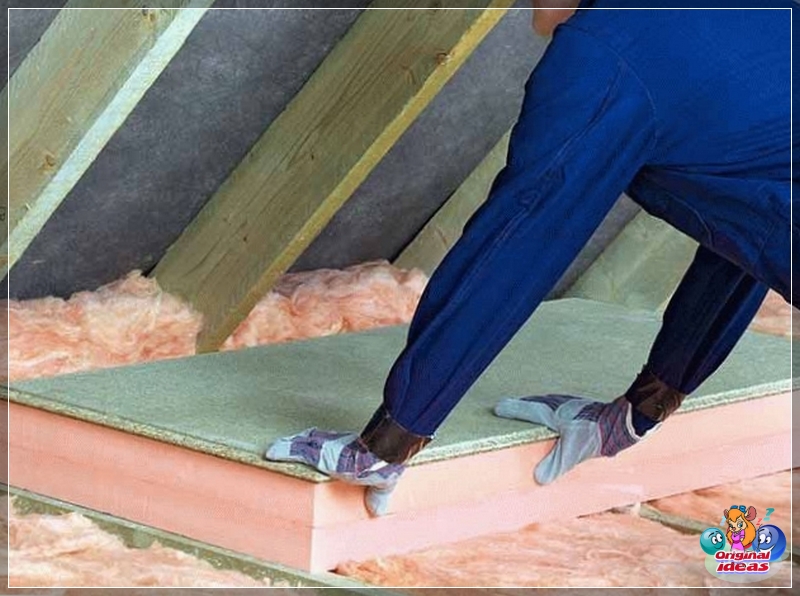

If you insulate the beam ceiling with expanded clay, then it is enough to fill the space between the beams with it. Glass wool is laid as tightly as possible. If necessary, lay several layers of heat insulator, making sure that their joints at different levels do not coincide with each other. After laying, the insulation is covered with another membrane. Above it, you can lay a floor of boards, plywood or OSB.

For insulation of slab and monolithic floors, you can make a screed from expanded clay concrete or mortar from:

The screed is placed on the waterproofing membrane.

For the device of thermal insulation from glass wool, clay, expanded clay, it is better to make a wooden crate.

Warming with modern materials

Modern materials are increasingly used to insulate the ceiling in a private house. Manufacturers produce both slab and roll, as well as backfill and blown insulation. They can be used on any type of floor, however, some types of thermal insulation have not become widespread due to the high price and cost of work.

The most effective way to insulate ceilings with foam today.

Manufacturers assure that polyurethane foam sprayed onto the floor surface will not lose its heat-shielding properties for half a century. It is lightweight, does not lose shape, is environmentally friendly, has the qualities of a sound insulator. After spraying with polyurethane foam, there are no cold bridges. Polyurethane foam has excellent contact with metal surfaces and protects them from oxidation. Insulation does not need hydro and vapor barrier. Nevertheless, the need to use specialized equipment in the work and the high price of the material negatively affect its popularity.

The process of applying ecowool is similar to polyurethane foam insulation. It is usually sprayed with special equipment, but it can be replaced with a garden vacuum cleaner and a corrugated hose. Ecowool is sometimes laid by hand.

Warming with expanded polystyrene

Most home owners prefer to use cheaper thermal insulators, which include:

Expanded polystyrene can be foamed and extrusion. The factories produce both slabs and granular material. With loose expanded polystyrene, the ceiling can be insulated only from above. The process looks the same as thermal insulation with expanded clay. Slab foam and extruded polystyrene foam can be pasted over the floor from the inside, but it is undesirable to do this in residential premises.

Stacking EPS boards on the ceiling can create a solid floor. The insulation does not need waterproofing, but the concrete surface must be treated with an antiseptic compound and primed before laying. It is necessary that the slabs fit tightly to the floor plane.

At the preparatory stage, it needs to be repaired by filling up cracks and depressions, removing delamination and debris, and getting rid of protruding elements and bumps. The underside of the slabs can be adjusted to the ceiling surface with an abrasive tool. The panels are laid without allowing gaps between them. The joints are sealed with foam crumbs diluted in acetone. Expanded polystyrene can be glued to the ceiling with polyurethane foam. On the base from it you can lay boards, sheets of plywood, etc.NS.

Foam plastic slightly surpasses the extruded material in terms of heat protection, but much looser than it. Laying foam on the ceiling is better in a prepared crate. You cannot walk on it, so the crate is covered with a flooring. Above the foamed insulation laid without a frame, a reinforced concrete screed should be made.

Mineral wool insulation

For internal insulation, it is better to use mineral wool. One of its types, slag, is produced in the form of rolls. Basalt (stone) wool is produced in the form of slabs, rolls and mats. Materials are similar to glass wool, but safer for health. The best characteristics among mineral insulators are stone wool.

Insulation of the ceiling with mineral wool from the outside is carried out in the same way as glass wool. For its installation under the ceiling, the installation of the lathing is required. It is easier to build it under a wooden floor. Under a concrete ceiling, the frame is best made from beams fixed on opposite walls. The insulation must be protected by waterproofing from the ingress of water from above, and a vapor barrier, which will not allow rising vapors to penetrate into its thickness. The upper membrane is fixed to the ceiling prior to the installation of the battens.

The width of the insulation should be greater than the distance between the beams: in densely laid insulation there will be no room for gaps.

Mineral wool can be laid in several layers, but the total thickness of the insulation must correspond to the width of the beams. From below it will be supported by a counter-lattice or a false ceiling. There is no need to purchase a thicker insulation: it will have to be laid, crushing, thereby reducing the thermal protective qualities of the material.

Foil polyethylene foam can be used to insulate the floor from the bottom and top. It is fixed on a plane with glue. Threaded fasteners damage the coating of the material, which adversely affects its performance. There are self-adhesive types of thermal insulation. The advantage of foamed polyethylene foam is its small thickness. With internal insulation of the ceiling, the height of the room hardly changes.