Over time, any bath loses whiteness and shine, enamel is erased, the bottom is covered with cracks.

This happens due to hard water, active powders, in the process of not accurate use, due to a thin or non-quality layer of enamel.

The bath has become unusable and something needs to be done with it.

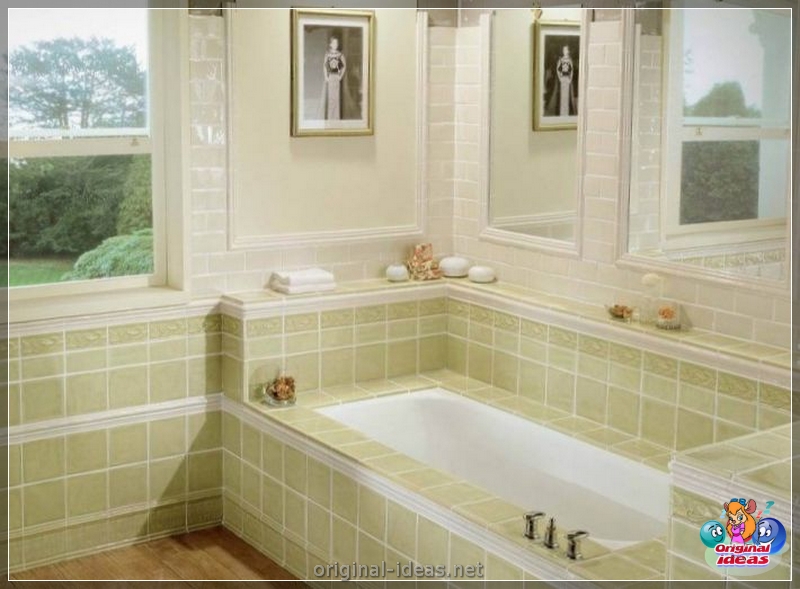

All of us comes thoughts about the restoration of a cast -iron bath or buying a new. Consider everything for and against. Buying a new bath, you will spend much more funds than restoration. It must be remembered that the legs or frame in which it is installed is purchased for the bath.

And what is the dismantling and removal of the old bath! Since the room is very small, it is inconvenient to work in it, during dismantling, you can damage the repair.

If you have a cast -iron bath, then keep in mind that now baths are not produced and the best solution will be to preserve and reanimate it. Cast iron bath has a lot of advantages over others. She is reliable, durable, durable, excellently retains heat.

A great option in this case would be restoration. This procedure costs much less than a new bath. And if you invite an experienced specialist, restoration will take only a few hours.

There are such methods of restoration as enamel coating, liquid acrylic coating and the establishment of an liner from acrylic.

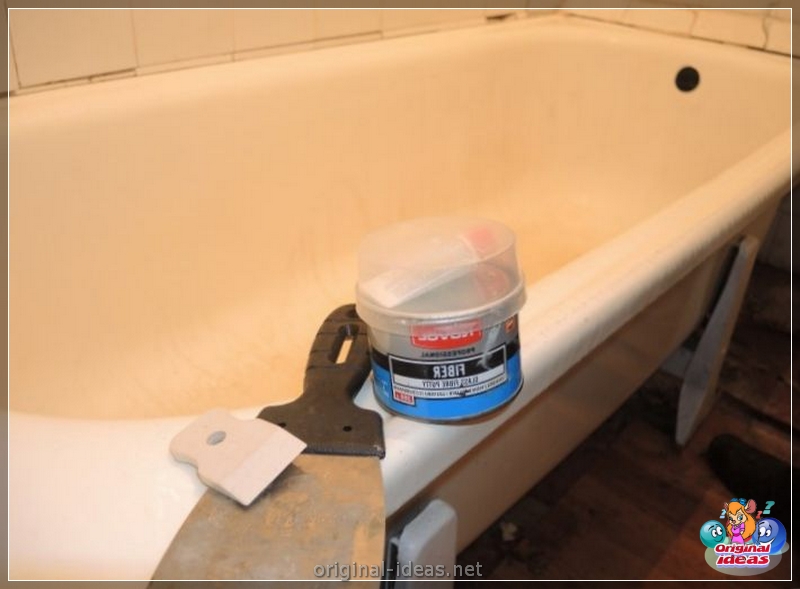

Bath restoration enamel is one of the common types of repair. Already familiar from Soviet times, when it was not possible to get a new bath. The technology of the enameling process is akin to painting.

Not every paint is suitable for coating the enamel of the bath. This procedure is designed for 3-5 years. Then you need to change the enamel again.

The advantages of this method are cheaply, cast -iron and steel bath are subject to restoration, it is used without dismantling. Cons - the coating turns yellow quickly, dries for a long time, has sensitivity to blows.

This is a new way of restoration. During its use, he has established itself positively. A special composition is bought for the restoration of the bath with liquid acrylic and according to the instructions is painted by pouring.

The material is quite durable, consists of hardener and acrylic. The ingredients are thoroughly mixed and applied to the bath immediately before use.

The advantages in this case are rapid drying, coating strength, resistance to mechanical damage, lack of yellowing over time, resistance to detergents, good thermal conductivity.

Of the minuses, one can note the high cost of the solution, removing the siphon before processing and not eliminating the factory marriage in the form of bathtub irregularities.

This technology is so simple that you can easily cope with it. DIY bath restoration will not take much time and effort. Regardless of the restoration method, the bath cleaning is carried out the same.

It should be perfectly clean. We cover the bath with acrylic as many times as the instruction requires. Leave to dry for 48 hours.

An acrylic liner is considered a simple type of bathtub repair. They are produced at the factory. Shops sell them in large quantities.

Professionals recommend not to pick up water for about two weeks, but you can use the shower. This operation allows the liner to better attach. Manufacturers give a guarantee for 10 years of using the tab, taking into account the correct installation.

Before the installation, the liner is prohibited, for the cutting out of the drain. Sometimes you have to independently adjust the dimensions of the bath. Having drilled the opening for the plum, you can prepare for the installation of the liner.

It is attached with mounting foam in stripes after 10cm. On the sides we put foam very tightly. Install and fill the bath with water, drain after day.

The advantages of this method are speed and ease of installation, you can do it yourself. The disadvantages include high cost and reduction in the area of the bath.