Seamless stretch ceilings have become quite a fashionable and popular attribute of apartments, private and country houses, the owners of which follow modern trends in design. Nowadays, such designs are produced in a wide range, which allows you to choose them for any premises and for every taste. The ceiling is the most important element of the interior, which is always in sight and often forms the first impression of the owner, and therefore the significant costs of the tensioning system fully justify themselves.

Design features

In general, a stretch ceiling is a canvas stretched in a baguette (frame) over the entire ceiling surface at a short distance from the ceiling. This seamless construction is characterized by the use of a single piece of large size. This fact ensures the perfect smoothness of the ceiling.

Until recently, only seamless fabric stretch ceilings with a polyester fabric, knitted fabric were installed. The technology makes it possible to provide the width of such canvases up to 5-6 m, which is enough to cover large areas. Now the production technology has been developed for plastic and PVC film sheets up to 4-4.5 m wide, which can compete with the fabric version.

The main advantages of seamless ceilings are decorativeness and aesthetics, the integrity of the canvas allows you to apply huge colorful panels of various themes to the entire surface. No seam improves mechanical strength and durability. With the help of such a structure, you can form a ceiling of various shapes - a perfectly flat, horizontal surface or ceiling vault, arched and hipped surface.

Fabric ceiling

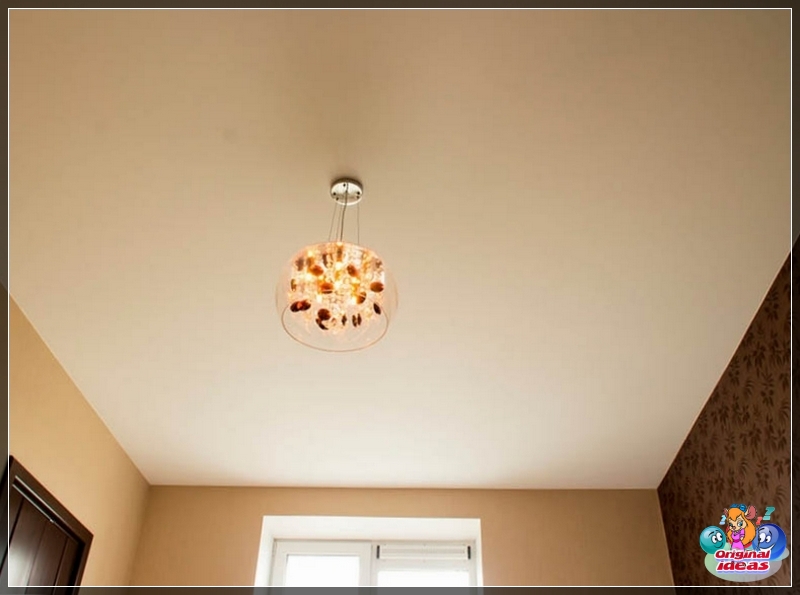

The name "seamless stretch ceilings" comes from fabric structures, t. To. such canvases can only be stretched in one piece. This option remains the most popular. Modern canvases are made from high-strength polyester yarn and impregnated with polyurethane resins. Examples of fabric ceilings are shown below in the photo.

The main advantages of fabric ceilings:

The web is tensioned at room temperature, without heating. The following disadvantages are also noted: air permeability, reduced elasticity (low elongation during stretching), the ability to accumulate dirt between the threads. Limits the use of fabrics increased cost. Their color gamut is limited, but the problem is solved by coloring.

Varieties of fabric ceilings

Taking into account the surface texture, fabric ceilings are divided into the following types:

Another important classification is the method of fastening the canvas in a baguette. In fabric constructions, there are 2 main options:

According to the method of finishing, decorative and white matte or semi-gloss canvases are distinguished. In the first case, ready-made models of a certain color are implemented with or without a pattern. It should be borne in mind that it is quite difficult to stretch canvases with patterns, t. To. any unevenness noticeably distorts the drawing. In addition, the assortment of decorative canvases is not very large, and therefore the second option is often preferred. They are cheaper and are designed for hand staining and painting, and withstand up to 5-6 stains. In this case, you can use paints of different colors, which expands the design possibilities.

Installation technology

Installation of seamless stretch ceilings can be conditionally divided into several stages - preparation of the working area, installation of a baguette (frame), tension of the canvas and finishing (if necessary). The preparatory stage includes cleaning the ceiling from old coating and poorly fixed plaster, sealing large defects, removing dirt and treating areas with mold and mildew. Careful leveling of the base surface is not carried out, because. To. the canvas hides all defects and irregularities. Align the upper part of the wall, where the profiles of the baguette are fixed. They should fit snugly to the surface and be located strictly parallel to the wall.

An important step is marking the location of the baguette. Its profiles must be fixed strictly parallel to the floor, and therefore the correct marking significantly affects the quality of the ceiling. To do this, the lowest corner of the room is found and the first mark is made in it at a distance of 3-6 cm from the ceiling. The distance depends on the need to lay communications under the canvas and the installation of insulation. A tape measure measures the height of this point from the floor, and then it is measured in all corners. The resulting corner marks are connected to each other by lines along the wall, beaten off with a stretched, painted cord.

The second stage is the installation of the baguette. For this, profiles are preliminarily attached to the wall and the attachment points are marked. In these places, holes with a diameter of 8-10 mm are made with a perforator or an electric drill. Plastic dowels are driven into them. Profiles with the necessary fasteners are fixed in dowels with self-tapping screws around the entire perimeter of the room, forming a continuous frame. The horizontal position of their location is controlled by the building level.

The most crucial stage is the stretching of the fabric. The process starts from the center. First, on one of the walls, using a spatula, the edge of the fabric is pushed under the glazing bead and fixed with it. Then the same action is carried out on the opposite wall with manual tension of the canvas. Similarly, the fabric is fixed on 2 other walls. Thus, the stretching begins with securing the canvas in the form of a cross. Further, it is fixed gradually and evenly, it is necessary to move from the center to the corners of the ceiling. Excess canvas is cut off, but one nuance should be taken into account. Removal of excess fabric ensures the neatness of the structure, but if there is no stock, it will be impossible to reuse the fabric. In this matter, an alternative is needed - a maximum margin is left that does not spoil the appearance of the ceiling.

Film construction

For seamless stretch ceilings, PVC film with a thickness of 0.2-0.4 mm and a width of up to 4-4.5 m can be used. Plastic canvas has a number of fundamental differences from fabric construction. First of all, they are associated with stretching technology. Plastic cannot be pulled mechanically, because. To. it just lengthens when stretched. Taking this into account, the tension is provided only by the thermal method. When heated, the material expands and in this form is fixed in the frame, and when cooled, it contracts, which provides tension.

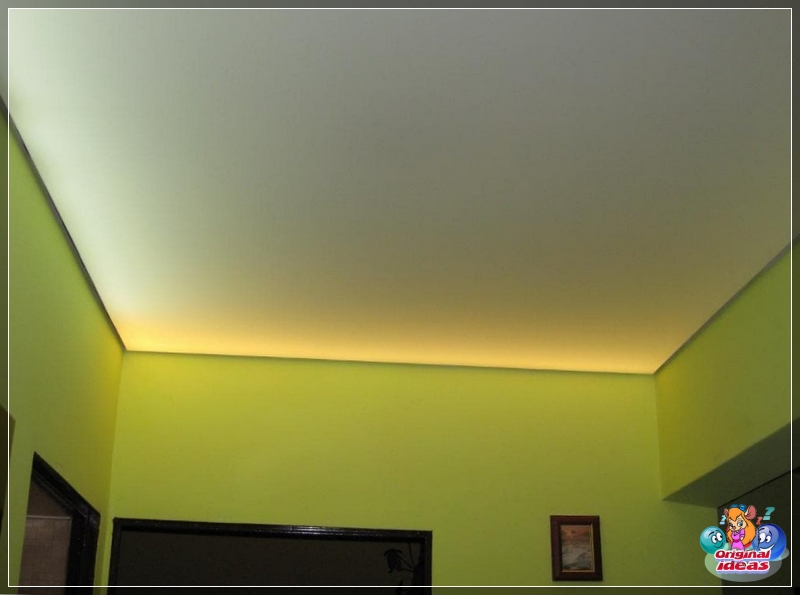

Differences in appearance and decoration are significant. PVC film usually forms a glossy surface with increased reflectivity. Other options (matt, satin) are only possible with special surface treatment. It is impossible to paint the film with high quality, and therefore the coloring is provided only at the stage of making the canvas. However, the assortment of colors is extensive, which makes it possible to choose for every taste. The surface pattern is also created at the production stage. For this, thermal transfer and photo printing are used. In other words, PVC cloth must be matched by color and pattern, and it will no longer be possible to change them. An example of a ceiling is shown in photo 2.

The advantages of a film ceiling are: water resistance, which excludes the harmful effects of a flood from above; perfect smoothness and evenness of the surface after stretching; variety of colors and patterns; durability and long-term color retention; low cost. Disadvantages: low resistance to cutting and stabbing influences, the need for heating during installation, air tightness, a tendency to accumulate condensate, limitation in the power of lighting equipment, limitation of the width of the room (no more than 4 m).

Technological features

The preparatory stage for the installation of a plastic ceiling does not differ from the installation of a fabric structure. A baguette for him can be based on glazing bead fasteners. However, the harpoon-type fastening is most often used, which is not used for stretching the fabric. Fastening of baguette profiles is carried out using dowels.

The tension of PVC-cloth is fundamentally different from the installation of a fabric ceiling.

Indoors at the time of work is set at a temperature of at least 30 degrees (the higher the better). Before installation, the film is heated with a heat gun, a powerful construction hair dryer or a heat fan to a temperature of 60-65 degrees. Securing the canvas starts from the corners and gradually shifts towards the center. Film ends are pulled into fasteners with a spatula.

Manufacturer's choice

The reliability and durability of stretch ceilings depends on their quality and the technologies used in production. Attempts to save money often lead to rude fakes on the ceiling. Poor-quality canvases begin to creep away already at the stage of stretching.

In order to avoid problems, you should opt for trusted manufacturers.

French, German, Italian, Swiss companies will be distinguished by their high quality and attractive appearance. Among the manufacturers of seamless ceilings, such recognized leaders stand out - Descor (Germany), Cerutti (Italy), Clipso (Switzerland). It is important that Russian-made baguettes are suitable for most models, which makes repairs easier.

These companies offer an extensive product range. In particular, the German company Descor produces seamless ceilings in the following categories: Trevira (elite products at a high price), Fr (economy class with a reduced cost), Color (models in different colors) and Acoustic (ceilings with noise insulation properties).

Conclusion

Seamless tension structures can provide an attractive design in any style, even on overly uneven ceilings. Such ceilings, with proper installation, will serve for a long time and reliably. The rather high cost of these products requires a serious approach to the choice of the material of the web and the fastening system. The installation can be carried out independently, but if there is doubt about your own abilities, it is better to involve specialists.